- Home

- Service and Support

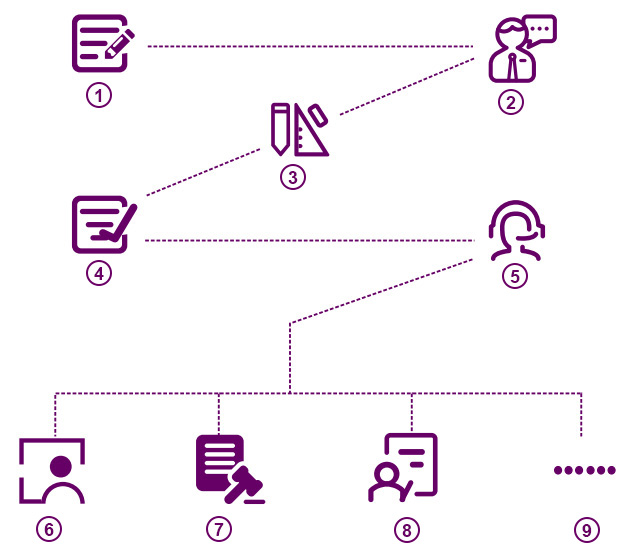

Bo Tsing will keep in touch with our customers to find out the specific needs of their applications, we provide automatic welding solutions for large-scale structural parts according to metal types, metal specifications, welding position, dimension of the weld seams, welding codes and standards, acceptance criteria, etc. We will also provide welding procedure specification (WPS), operator training services and other aftersales supports.

- Understand customer requirements

- Confirm requirements by two parties

- Develop automatic welding solution

- Sign the contract

- After-sales service

- Robot operator(in-house or on-site) training and demonstration

- Procedure qualification record (PRQ)

- Operator training for operating welding robot

- More

Our welding robots are certified by CE and CR certificate. In addition, Bo Tsing Tech has created its own quality standards which are higher than the national and EU standards, and we entrusted an authoritative third-party to perform related tests, in which all requirements are met.

ManufacturingWe established long-term strategic cooperation with reliable suppliers to ensure the stable supply of high-quality materials and parts. We adopt ISO9001 quality management system, and modern international quality management systems including FMEA and 8D to implement full inspection of incoming materials, in-process control, and finished product quality control.

InspectionBefore leaving the factory, all welding robots need to undergo a series of tests including sliding test under load, magnetic flux test, motion performance test, insulation test, which are verified by all-position test platform, curved surface tracking test platform, pipe test platform, etc., so as to ensure that product functionality and performance fully conform to the standards.

Dust proof test

Dust proof test Waterproof test

Waterproof test Waterproof test

Waterproof test Salt spray test

Salt spray test Vibration test

Vibration test

Our around-the-clock services starts from pre-sale services all the way towards after sales . According to the specific requirements of customers and projects, Bo Tsing Tech provides customized welding solutions, product selection suggestions, and WPSs (Welding Procedure Specifications). After-sale services cover product calibration, maintenance, operator training and spare parts supply.