- Home

- Products

Trackless unguided all-position crawling robots are integrated with different welding processes, modern welding automation technology and advanced laser vision sensing technology, enabling automatic welding of vertical seams and curved & irregular surfaces in the fields of oil and gas chemical industry, shipbuilding, nuclear power, energy, rail transit, etc.

-

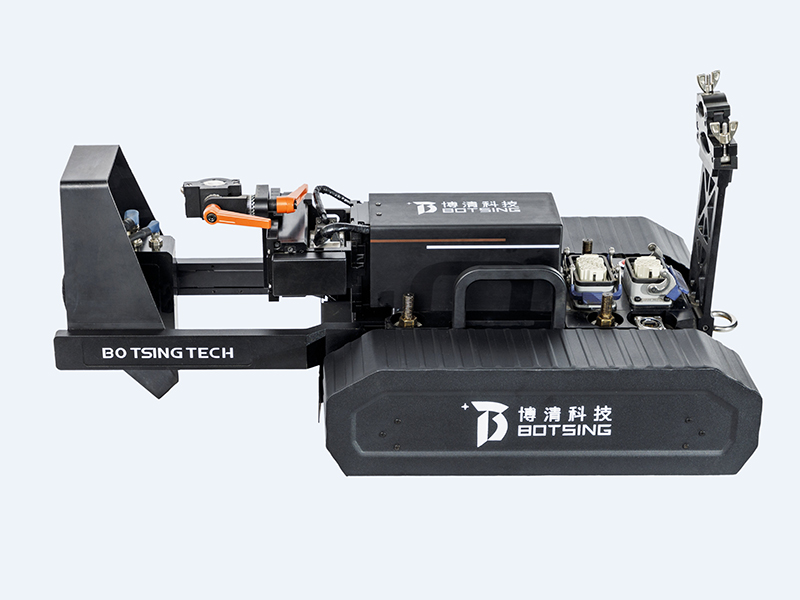

- Trackless Unguided All-position Crawling Welding Robot

Trackless Unguided All-position Crawling Welding Robot is a kind of intelligent welding system that can automatically track welding seams without the need for guiding tracks, it is an extremely sophisticated system with combination of AI, algorithm, welding automation, Laser vision sensing, Multi-sensor integrated control and multiple condition adaptive technology;

The new generation robot is capable of welding from 1 to 6G positions with turning capacity of spinning around 360 degrees, it is driven by caterpillar tracks, total weight of the robot is only 28.8kg but with max load of 60kg, it is integrated controlled by crawling mechanism, laser vision control system and more than 100 algorithms. It automatically adapts to gradual weld seam and sudden changes, it achieved for the first time on automatic crawling and weld seam tracking without need for tracks or programming, its Weld tracking accuracy reached ± 0.2mm.

-

- Trackless Unguided Pipe Welding Robot BOT-WTP27-121 is specially designed for automatic pipe welding, which can be applied to pipes diameters between 168mm to 1800mm. System is mainly composed of a crawler, a control cabinet, machine vision tracking system and welding load with no tracks or guide needed. Through machine vision tracking system, groove information such as weld width, throat depth and bevel angle can be acquired in real time to fulfill± 0.2mm precision automatic tracking.

Currently, welding of large-scale structural parts is performed mainly by manual or semi-automatic welding. A lot of hidden costs will be needed in the manual welding operation. A human welder needs to be trained for a long time to achieve sophisticated skills for quality welding operation. They may make mistakes during manual welding to affect production time, weld quality and costs. Manual welding may cause health and safety problems to the human welders due to the hazardous working environments full of flash, fumes, sparks, and heat. Semi-automatic welding in large structural components is affected by guiding tracks, which limits its degree of automation especially in the application scenarios with curved and irregular surface welds. Comparing with manual welding and semi-automatic welding, trackless unguided all-position robotic welding is an optimal alternative in the large-scale structural parts manufacturing industry, which can greatly improve welding quality and efficiency.

Unstable weld quality

Unstable weld quality  Low efficiency

Low efficiency  High labor costs

High labor costs Pneumoconiosis

Pneumoconiosis Employee risks

Employee risks  High management costs

High management costs

Guiding track needed

Guiding track needed Not applicable to the welding of irregular seam, especially curved surfaces

Not applicable to the welding of irregular seam, especially curved surfaces